The Tyre Collective

The Tyre Collective

Venture to mitigate the second largest

source of microplastic pollution in our environment

2019 – 2020

12 weeks (ongoing)

Role:

Lead Primary & Secondary Research and

Interdisciplinary collaboration and facilitation with experts;

Defined product and business strategy;

Prototyped with electronics & code for the product.

Awards

Mayor Of London’s Entrepreneur Award 2020

Sustainability Winner (20K GBP)

James Dyson Award

UK National Winner (10KGBP)

Imperial Venture Catalyst Challenge

Moonshot Prize (10K GBP)

Core77 Design Awards

Commerial Equipment Runner Up

Fast Company Innovation By Design Awards

Finalist

Tyres: The stealthy microplastic pollutant

we never thought about.

What happens when tyres wear down?

We all know tyres wear down, but never stop to consider where they go. Tyres wear out from friction every time we brake, accelerate or turn a corner. The particles become airborne affecting our lungs. More are swept into our waterways and oceans eventually entering our food chain. In fact, tyre wear emissions account for nearly half of PM 2.5 emission from road transport and are the second-largest microplastic pollutant in our ocean after single-use plastic.

The amount of tyre wear produced by London Buses, EVs, and cars. The No. 9 London bus, on average releases 4.65g per journey

and a total of 65g a day. Car and EV quantities based on a 16km UK average commute per day

An electric future

Electric vehicles (EV's) and stringent regulations will lower tailpipe emissions in the future. As EV’s are heavier than gas vehicles because of their battery, studies have shown that tyres would wear at a faster rate, increasing tyre wear emissions from 7 kilotonnes in 2015 to nearly 10 kilotonnes by 2030 in the UK. As we transition to EVs, it is crucial to consider the implications of tyre wear, so we are not replacing one pollution source with another.

Future vehicle pollution will not come

from tailpipes, but from tyres.

What if cars could clean up after themselves?

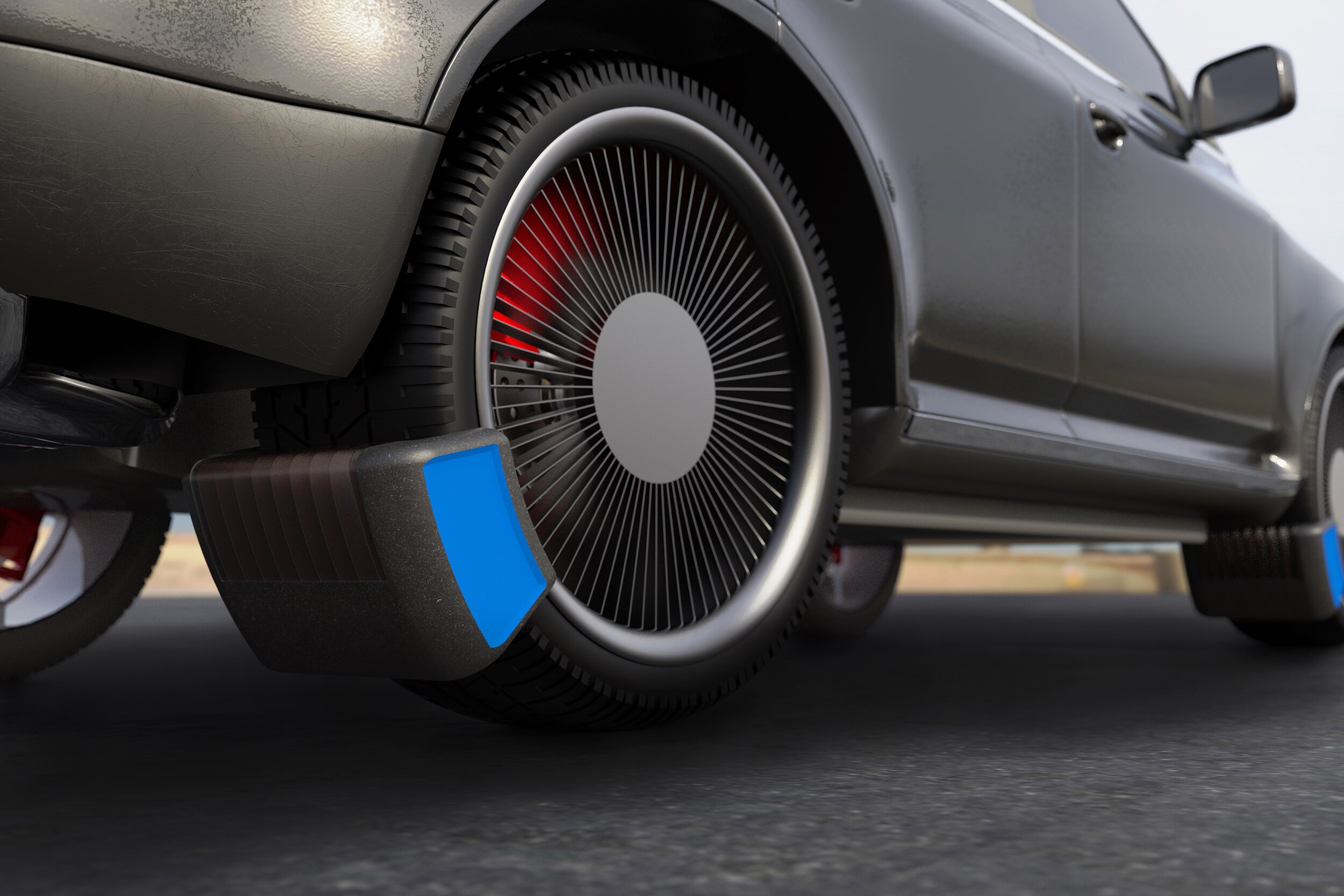

So we invented a device that captures tyre wear

Electrostatics & Aerodynamics

Carbon in rubber particles are positively charged as they fly off of the tyre. What started off with rubbing a balloon against a sweater, eventually led to our device that directs and collects charged particles with electrostatics as a guiding principle. Currently, our device collects 60% of all airborne particles. The device is positioned close to where the tyre meets the road. Working with the Imperial Department of Aeronautics we identified this position, to take advantage of airflow and Magnus effect of the spinning wheel.

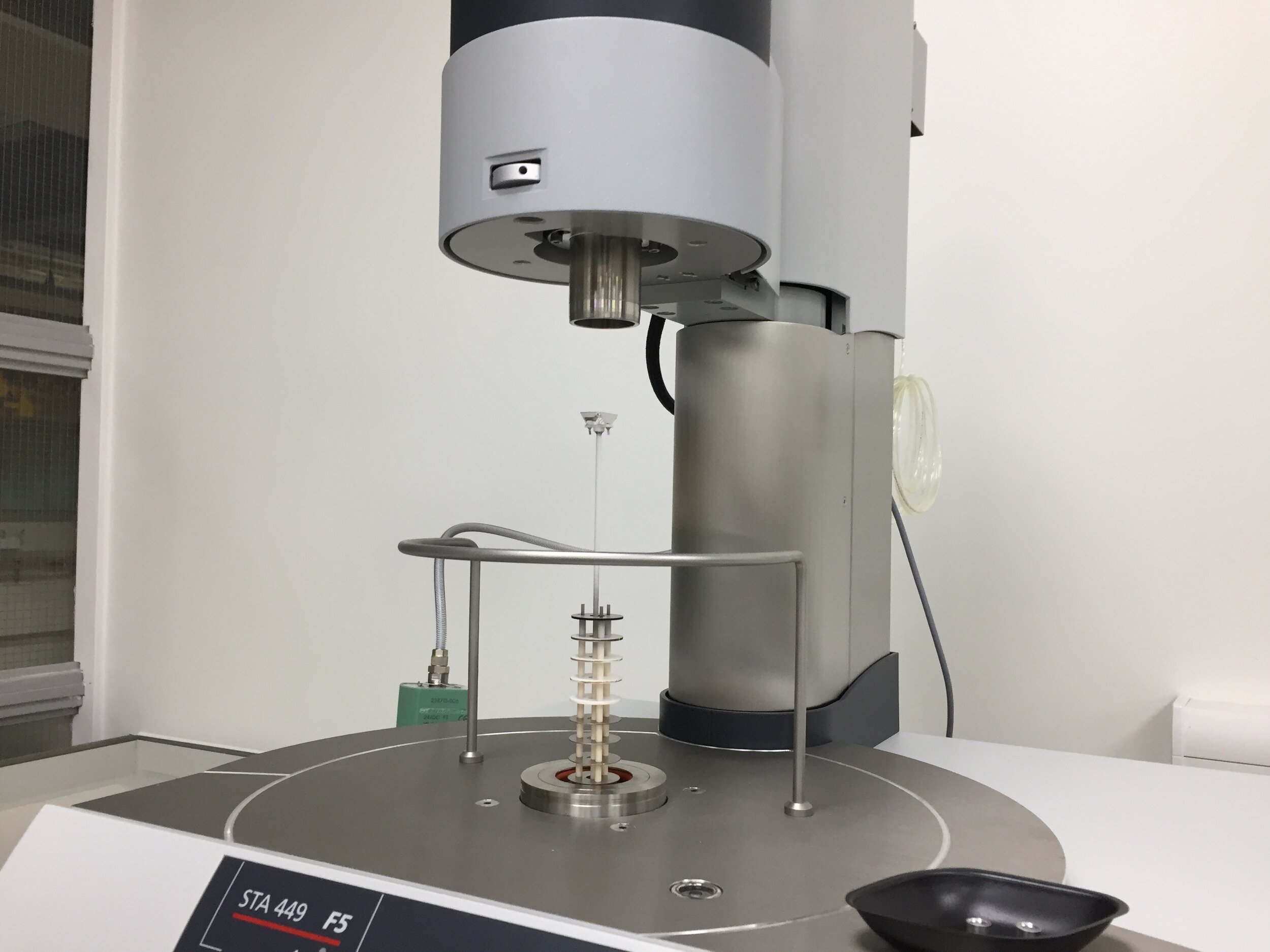

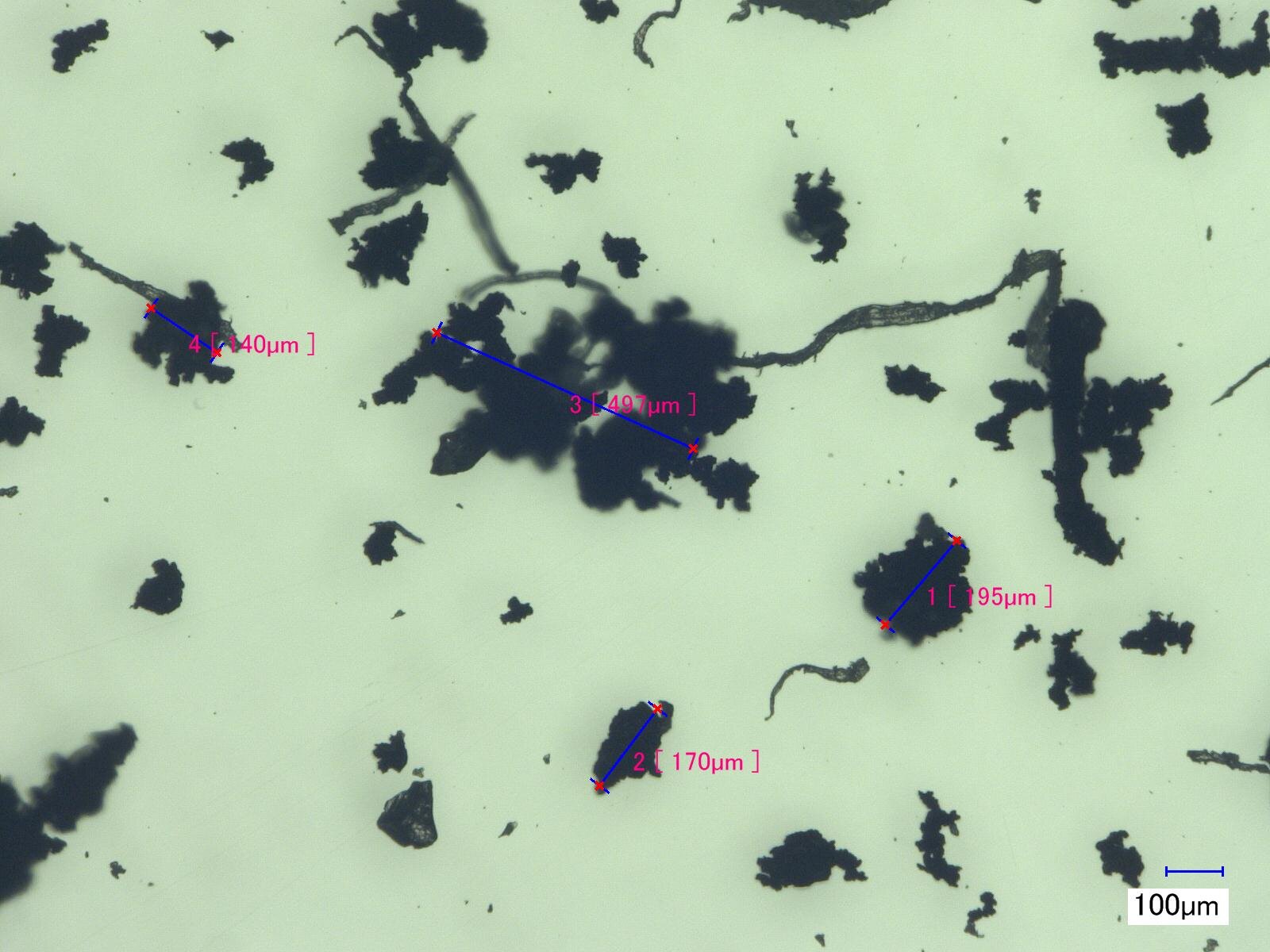

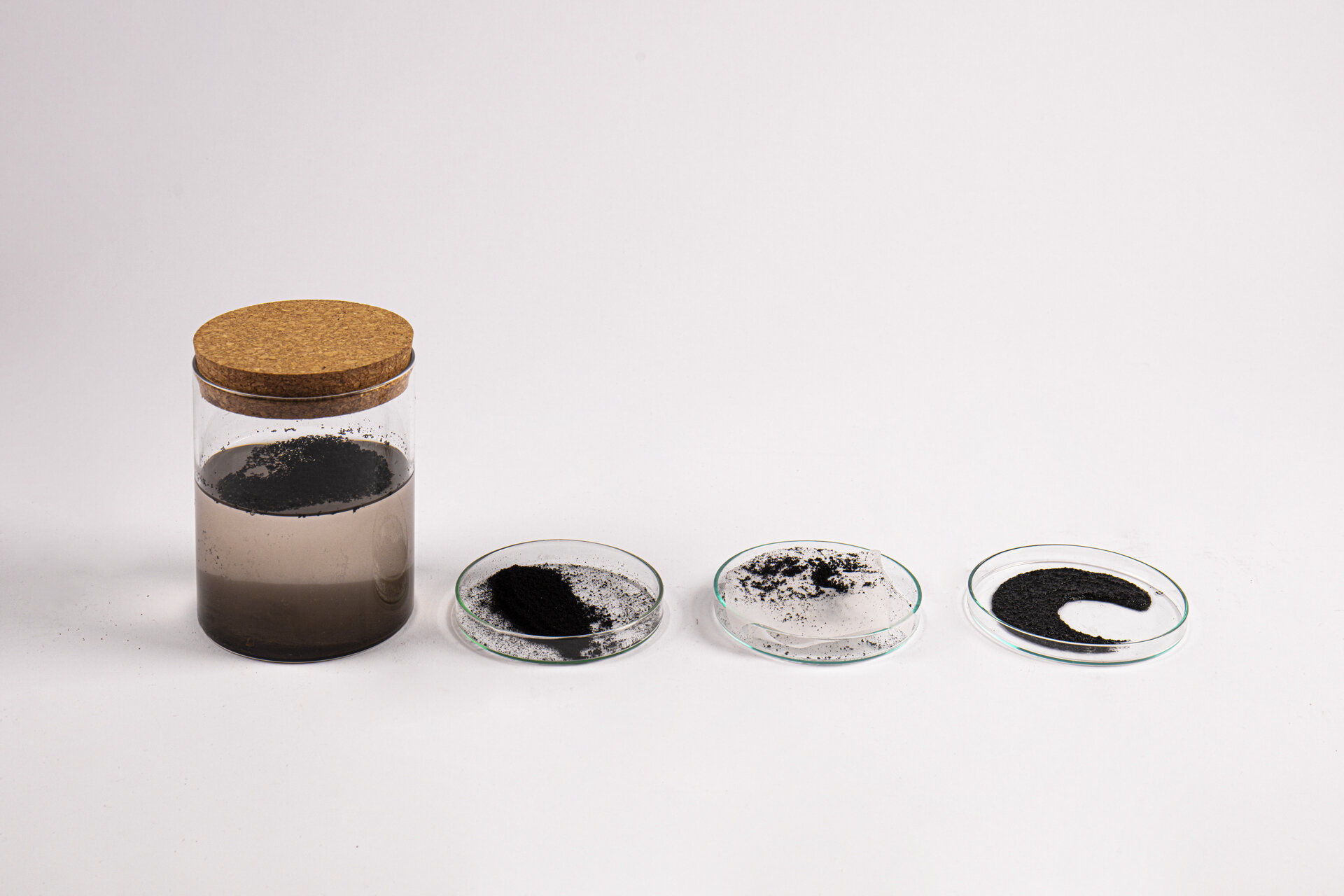

Closing the Loop

With an aim to create a closed-loop model after collection, these fragments are separated using simple techniques. Particles under 50 microns are small enough to be reused in new tyre walls, and other exciting applications.

Exhibitions

Dutch Design Week 2020

Imperial Lates: Future Commuter 2020, London

Material Driven, Architects@Work, Bilbao

RO Guiltless Plastics Prize Finalist, Milan

Making & learning

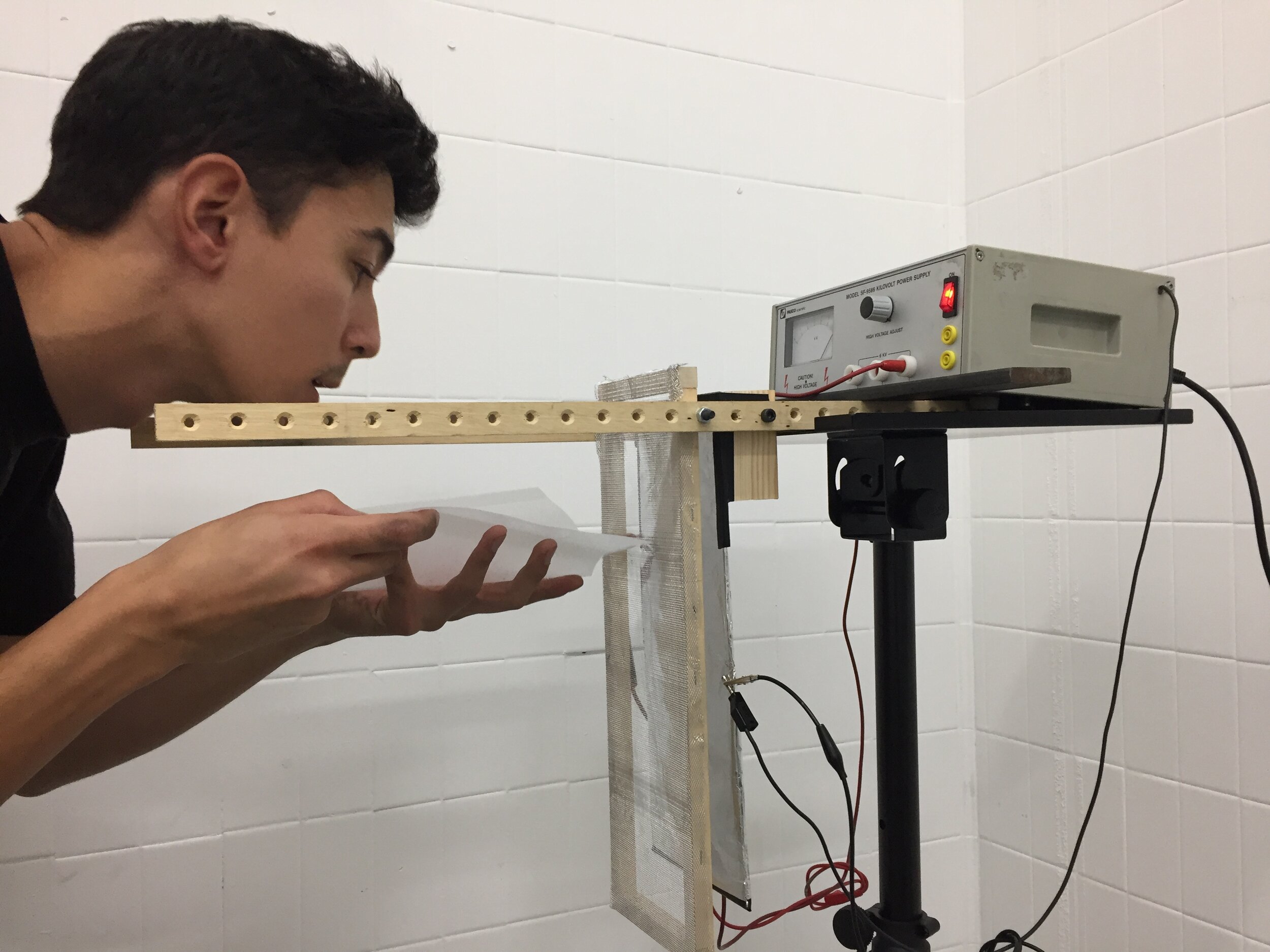

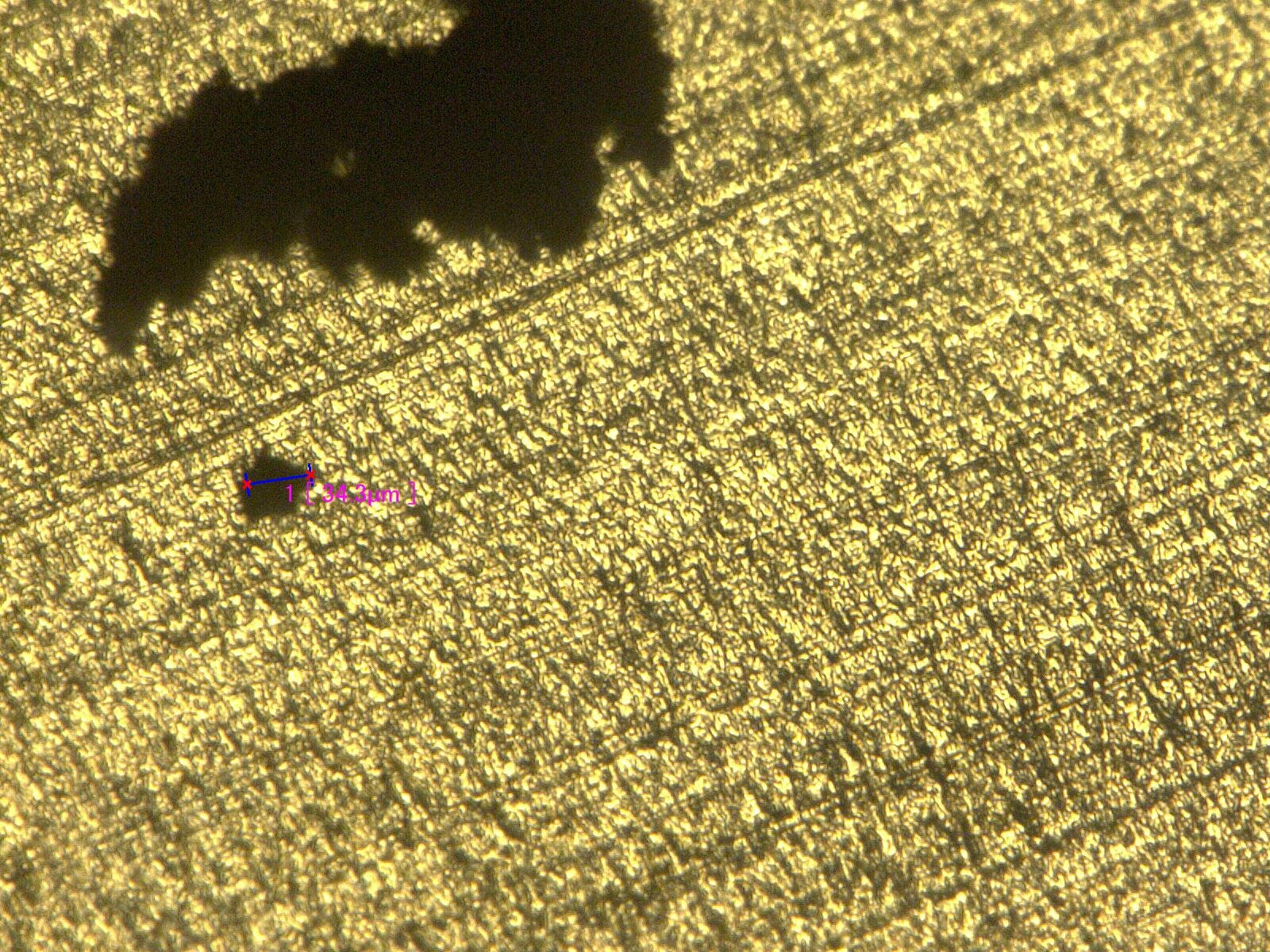

We explored various methods like vacuuming and adhesives but our discovery started with an observation—rubbing a balloon against a sweater and watching shaved tyre particles dance. This led us to hypothesise that the rubber itself was charged and that we could use electrostatics to capture it.

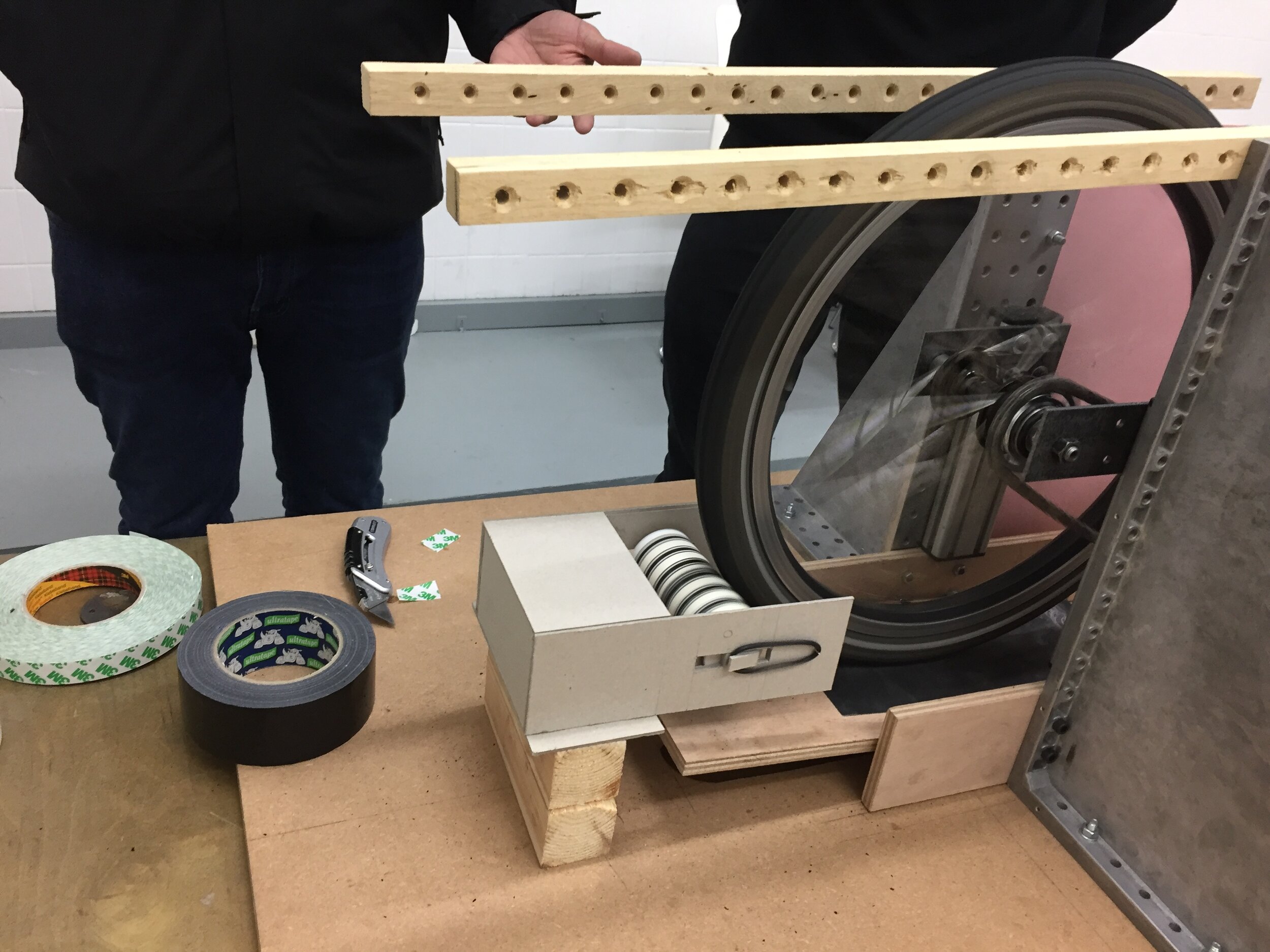

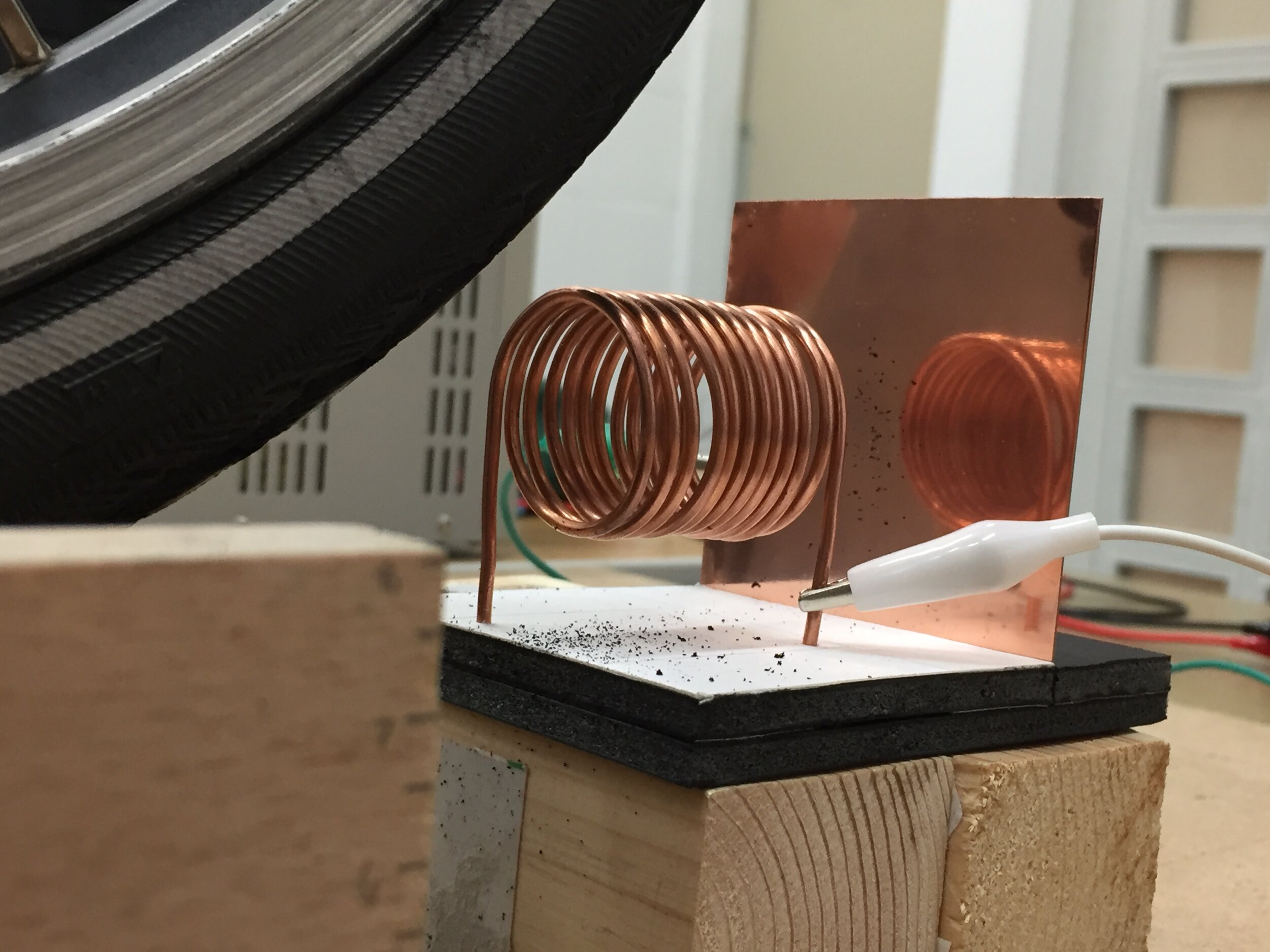

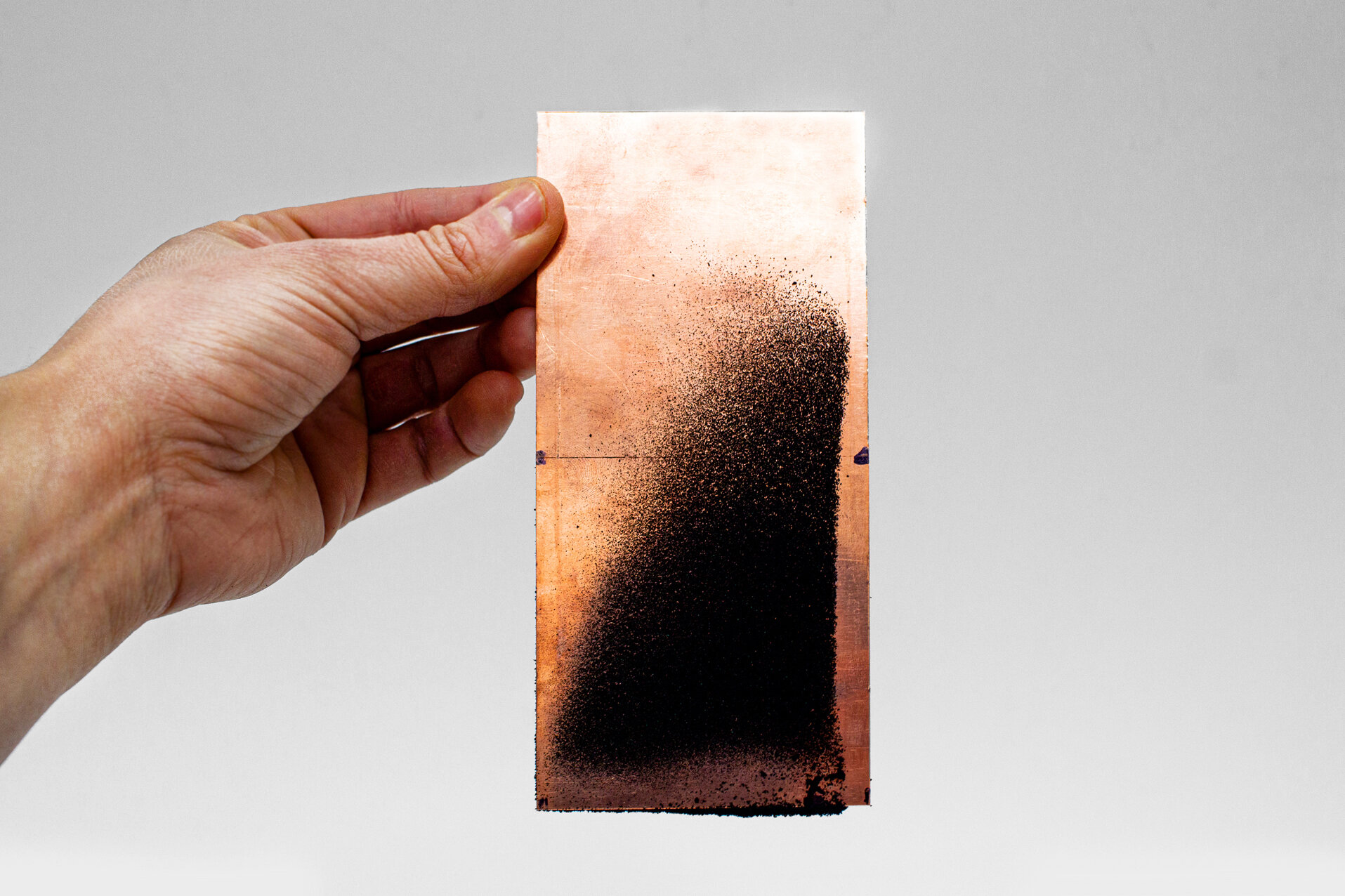

To test our theory we built a rig, spinning a bike wheel against a sprung road to mimic a tyre skidding. Our early prototypes were built in card, foamboard and copper, experimenting with various typologies and configurations of charged plates to maximize surface area and collection efficiency.

Initially powered by an external power source, we also tested batteries and built our own Van de Graaff generator.

Since the particles are pre-charged we only require a single array of electrostatic plates powered directly from a dynamo, stepping up the voltage as required.

To validate this problem in the context of London we collected road-sediment samples from different locations and identified a significant presence of tyre wear. To visualise the problem, we tracked TFL busses in realtime and calculated that a single bus produces 336g of tyre wear per day, a pile the size of a grapefruit.

Special Thanks to

Dyson School of Design Engineering

Prof. Robert Shorten

Dr. Chandramohan George

Imperial Department of Civil and Environmental Engineering

Dr Geoff Fowler

Dr. Marcus Yio

Imperial Department of Aeronautics

Dr. Nigel MacCarthy

Sang Nguyen

Imperial Department of Mechanical Engineering

Prof. Marc Masen